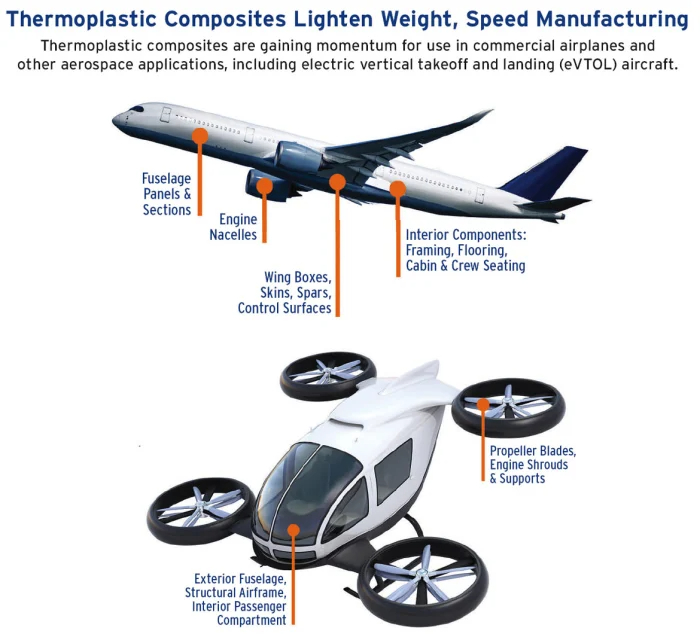

A cikin 'yan shekarun nan, an sami ci gaba da sauri na haɓakar fiberthermoplastic composites tare da resins na thermoplastic a matsayin matrix, kuma ana samun karuwa a cikin bincike da ci gaba na waɗannan manyan ayyuka a duk duniya. Thermoplastic composites ne composites sanya daga thermoplastic polymers kamar polyethylene (PE), polyamide (PA), polyphenylene sulfide (PPS), polyetherimide (PEI), polyether ketone (PEKK) da kuma polyether ether ketone (PEEK) a matsayin matrix da daban-daban ci gaba / katsewa. zaruruwa (misali carbon fibers, gilashin zaruruwa, aramid fibers, da dai sauransu.

Thermoplastic tushen man shafawa yawanci Long Fiber ƙarfafa Thermoplastics (LFT), MT pre-impregnated kaset da gilashin tabarma ƙarfafa Thermoplastics (CMT).

Dangane da amfani da buƙatu daban-daban, matrix resin yana da PPE.PAPRT, PELPCPES, PEEKPI, PA da sauran robobin injiniya na thermoplastic.

Thermoplastic matrix

Matrix Thermoplastic wani nau'i ne na kayan thermoplastic tare da kyawawan kaddarorin inji da juriya na zafi waɗanda za a iya amfani da su a cikin samfuran masana'antu da yawa. Thermoplastic matrix yana da babban ƙarfi, juriya na zafi da kuma juriya mai kyau na lalata.

Thermoplastic resins a halin yanzu da ake amfani da su a cikin aikace-aikacen sararin samaniya sune mafi yawan zafin jiki, manyan matrix resin, ciki har da PEEK, PPS da PEI, wanda amorphous PEI yafi amfani dashi a aikace-aikacen sararin samaniya fiye da Semi-crystalline PPS da PEEK, wanda amorphous PEI. yana da ƙarin aikace-aikace a cikin tsarin jirgin sama fiye da Semi-crystalline PPS da babban zafin gyare-gyaren PEEK saboda ƙananan zafin aiki da farashin sarrafawa.

Thermoplastic resins suna da mafi kyawun kaddarorin inji da juriya na sinadarai, zafin sabis mafi girma, ƙayyadaddun ƙarfi da taurin ƙarfi, ƙayyadaddun ƙayyadaddun ƙarfi da juriya na lalacewa, kyakkyawan juriya na gajiya, ikon yin hadaddun geometries da sifofi, daidaitawar thermal conductivity, sake yin amfani da su, kwanciyar hankali mai kyau a cikin matsanancin yanayi. , maimaita gyare-gyare, da weldability, da dai sauransu.

Abubuwan da aka haɗa wanda ya ƙunshi resin thermoplastic da kayan ƙarfafawa suna da fa'idodi da yawa kamar karko, babban ƙarfi, juriya mai ƙarfi da juriya mai lalacewa; fiber prepreg baya buƙatar a adana shi a cikin ƙananan zafin jiki kuma, lokacin ajiyar prepreg mara iyaka; gajeren sake zagayowar gyare-gyare, weldable, babban yawan aiki, sauƙin gyarawa; za a iya sake yin fa'ida kuma a sake amfani da tarkace; babban 'yanci na ƙirar samfuri, ana iya yin su zuwa sifofi masu rikitarwa, daidaitawar gyare-gyare mai faɗi, da sauransu.

Abubuwan ƙarfafawa

Gabaɗaya, tsayin gajerun fibers ɗin da aka ƙarfafa shi ne 0.2 zuwa 0.6 mm, kuma tunda yawancin zaruruwa ba su da ƙasa da μm a diamita, don haka gajerun zaruruwa suna kama da foda. Short fiber ƙarfafa thermoplastics gabaɗaya ana kera su ta hanyar haɗa zaruruwa cikin narkakken thermoplastics. Tsawon tsayi da yanayin bazuwar fibers a cikin matrix sun sa ya zama mai sauƙin sauƙi don cimma ruwa mai kyau, kuma gajerun abubuwan haɗin fiber sune mafi sauƙin ƙirƙira idan aka kwatanta da tsayi da ci gaba da kayan ƙarfafa fiber, amma tare da ƙarancin haɓakawa a cikin kayan aikin injiniya. Gajerun abubuwan haɗin fiber sun kasance ana kafa su zuwa sassa na ƙarshe ta hanyar gyare-gyare ko hanyoyin extrusion saboda gajerun zaruruwan suna da ƙarancin tasiri akan kwarara.

Dogon fiber ƙarfafa abubuwan haɗin gwiwa yawanci kusan mm 20 ne a tsayin fiber kuma yawanci ana shirya su ta amfani da filaye masu ci gaba da kutsawa tare da guduro sannan a yanke zuwa wani tsayi. Tsarin da aka saba amfani da shi shine tsarin gyare-gyaren pultrusion, wanda ake samar da ci gaba da motsi na gauraya zaruruwa da resin thermoplastic ta hanyar shimfiɗa zaruruwa ta hanyar gyare-gyare na musamman. A halin yanzu, dogon fiber-reinforced PEEK thermoplastic composites iya cimma tsarin kaddarorin na fiye da 200 MPa ta FDM bugu da modules na fiye da 20 GPa, tare da mafi aiki ta hanyar allura gyare-gyare.

Zaɓuɓɓukan da ke cikin abubuwan haɗin gwiwar fiber masu ci gaba suna "ci gaba" kuma suna da tsayi daga 'yan mita zuwa mita dubu da yawa. Ci gaba da hada fiber na gaba ɗaya ana samun su azaman laminates, prepreg tefs, ko braids, waɗanda aka kafa ta impregnating matrix thermoplastic da ake so tare da ci gaba da zaruruwa.

Menene halayen kayan haɗin gwiwar da aka ƙarfafa da zaruruwa?

Kwamfutar ta fiber da aka kirkira sune abubuwan da aka kafa ta hanyar iska, gyada ko kuma tsarin pirtrusion, fiber na carbus, da kuma kayan strusid, da kuma matriid fiber. Dangane da nau'ikan kayan ƙarfafawa daban-daban, abubuwan haɗin gwiwar fiber na yau da kullun sun kasu kashi-kashi na fiber fiber ƙarfafa composites (GFRP), carbon fiber ƙarfafa composites (CFRP) da aramid fiber ƙarfafa composites (AFRP).

Saboda halaye masu zuwa na haɗe-haɗe masu ƙarfafa fiber:

(1) ƙarfi mai ƙarfi da haɓaka mai girma;

(2) zane na kayan kaddarorin;

(3) kyakkyawan juriya da karko;

(4) coefficient na thermal faɗaɗa kwatankwacin na kankare.

Wadannan halaye saFRP kayanna iya saduwa da buƙatun sifofi na zamani zuwa babban tazara, hasumiya, nauyi mai nauyi, nauyi mai nauyi da ƙarfi mai ƙarfi, da yin aiki a ƙarƙashin yanayi mai wahala, da kuma biyan buƙatun ci gaban ginin masana'antu na zamani, don haka ana amfani da shi sosai. a cikin gine-gine daban-daban na farar hula, gadoji, manyan hanyoyi, ruwa, tsarin ruwa da tsarin karkashin kasa.

Danna nandon ƙarin bayani kan abubuwan da aka haɗa game da suGRECHO Fiberglass

Lokacin aikawa: Maris-31-2023